In digital designs, each and

every flip-flop has some restrictions related to the data with respect to the

clock in the form of windows in which data can change or not. There is always a

region around the clock edge in which input data should not change at the input

of the flip-flop. This is because, if the data changes within this window, we

cannot guarantee the output. The output can be the result of either of the

previous input, the new input or metastability (as explained in our post 'metastability').

This window is marked by two boundary lines, one pertaining to the setup time

of the flop, the other to the hold time defined as below.

Definition of Setup

time: Setup time is defined as the minimum amount of time before the clock's

active edge that the data must be stable for it to be latched correctly. In other words, each flip-flop (or any sequential element, in general) needs some time for the data to remain stable before the clock edge arrives, such that it can reliably capture the data. This duration is known as setup time.

The data that was launched at the previous clock edge should be stable at the input at least setup time before the clock edge. So, adherence to setup time ensures that the data launched at previous edge is captured properly at the current edge. In other words, we can also say that setup time adherence ensures that the system moves to next state smoothly.

Definition of Hold time:

Hold time is defined as the minimum amount of time after the clock's active

edge during which data must be stable. Similar to setup time, each sequential element needs some time for data to remain stable after clock edge arrives to reliably capture data. This duration is known as hold time.

The data that was launched at the current edge should not travel to the capturing flop before hold time has passed after the clock edge. Adherence to hold time ensures that the data launched at current clock edge does not get captured at the same edge. In other words, hold time adherence ensures that system does not deviate from the current state and go into an invalid state.

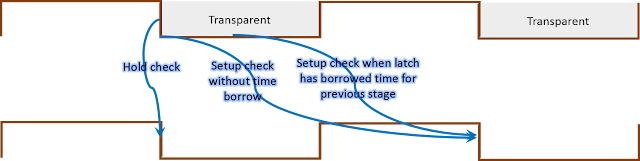

As shown

in the figure 1 below, the data at the input of flip-flop can change anywhere except within the seup time hold time window.

|

| Figure 1: Setup-hold window |

|

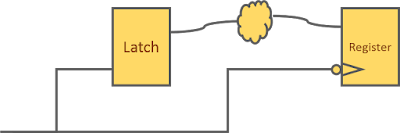

A D-type latch

|

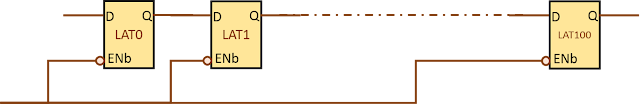

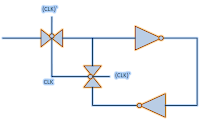

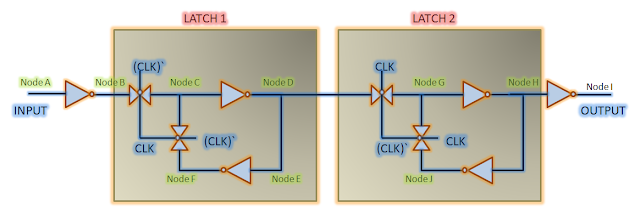

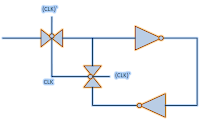

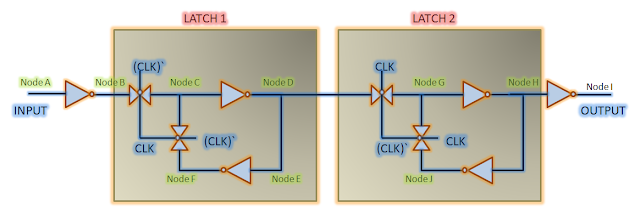

Cause/origin of setup time and hold time: Setup time and hold time are said to be the backbone of timing analysis. Rightly so, for the chip to function properly, setup and hold timing constraints need to be met properly for each and every flip-flop in the design. If even a single flop exists that does not meet setup and hold requirements for timing paths starting from/ending at it, the design will fail and meta-stability will occur. It is very important to understand the origin of setup time and hold time as whole design functionality is ensured by these. Let us discuss the origin of setup time and hold time taking an example of D-flip-flop as in VLSI designs, D-type flip-flops are almost always used. A D-type flip-flop is realized using two D-type latches; one of them is positive level-sensitive, the other is negative level-sensitive. A D-type latch, in turn, is realized using transmission gates and inverters. Figure below shows a positive-level sensitive D-type latch. Just inverting the transmission gates’ clock, we get negative-level sensitive D-type latch.

A complete D flip-flop using the above structure of D-type latch is shown in figure below:

|

| A D-type flip-flop |

Now, let us get into the details of above figure. For data to be latched by ‘latch 1’ at the falling edge of the clock, it must be present at ‘Node F’ at that time. Since, data has to travel ‘NodeA’ -> ‘Node B’ -> ‘Node C’ -> ‘Node D’ -> ‘Node E’ -> ‘Node F’ to reach ‘Node F’, it should arrive at flip-flop’s input (Node A) at some earlier time. This time for data to reach from ‘Node A’ to ‘Node F’ is termed as data setup time (assuming CLK and CLK' are present instantaneously. If that is not the case, it will be accounted for accordingly). Similarly, it is necessary to ensure a stable value at the input to ensure a stable value at ‘Node C’. In other words, hold time can be termed as delay taken by data from ‘Node A’ to ‘Node C’.

Setup and hold checks in a design: Basically, setup and hold

timing checks ensure that a data launched from one flop is captured at another

properly. Considering the way digital designs of today are designed (finite

state machines), the next state is derived from its previous state. So, data launched at one edge should be

captured at next active clock edge. Also, the data launched from one flop

should not be captured at next flop at the same edge. These conditions are

ensured by setup and hold checks. Setup check ensures that the data is stable

before the setup requirement of next active clock edge at the next flop so that

next state is reached. Similarly, hold check ensures that data is stable until

the hold requirement for the next flop for same clock edge has been met so that

present state is not corrupted.

|

| A sample path in a design |

Shown

above is a flop-to-flop timing path. For simplicity, we have assumed that both the

flops are rise edge triggered. The setup and hold timing relations for the data

at input of second flop can be explained using the waveforms below:

|

| Figure showing setup and hold checks being applied for the timing path shown above |

As shown,

data launched from launching flop is allowed to arrive at the input of the

second flop only after a delay greater than its hold requirement so that it is

properly captured. Similarly, it must not have a delay greater than (clock

period – setup requirement of second flop). In other words, mathematically

speaking, setup check equation is given as below (assuming zero skew between

launch and capture clocks):

Tck->q

+ Tprop + Tsetup < Tperiod

Similarly,

hold check equation is given as:

Tck->q + Tprop > Thold

If we

take into account skews between the two clocks, the above equations are

modified accordingly. If Tskew is the skew between launch and

capture flops, (equal to latency of clock at capture flop minus latency of

clock at launch flop so that skew is positive if capture flop has larger

latency and vice-versa), above equations are modified as below:

Tck->q

+ Tprop + Tsetup - Tskew < Tperiod

What if setup and/or hold violations

occur in a design:

As said earlier, setup and hold timings are to be met in order to ensure that

data launched from one flop is captured properly at the next flop at next clock

edge so as to transfer the state-machine of the design to the next state. If

the setup check is violated, the data will not be captured at the next clock edge

properly. Similarly, if hold check is violated, data intended to be captured at the next edge will get captured at the same edge. Setup hold violations can also lead to data changing within setup/hold window of the capturing flip-flop. It may lead to metastability failure in the design (as explained in our post 'metastability'). So, it is necessary to have setup and hold requirements met for

all the flip-flops in the design and there should not be any setup/hold violation.

What if you fabricate a design without taking care of setup/hold violations: If you fabricate a design having setup violations, you can still use it by lowering the frequency as the equation involves the variable clock frequency. On the other hand, a design with hold violation cannot be run properly. So, if you fabricate a design with an accidental hold violation, you will have to simply throw away the chip (unless the hold path is half cycle as explained here). A design with half cycle hold violations only can still be used at lower frequencies.

Tackling setup time violation: As given above, the equation for setup timing check is given as:

Tck->q + Tprop + Tsetup - Tskew < Tperiod

The parameter that represents if there is a setup time violation is setup slack. The setup slack can be defined as the difference between the L.H.S and R.H.S. In other words, it is the margin that is available such that the timing path meets setup check. The setup slack equation can be given as:

Setup slack = Tperiod - (Tck->q + Tprop + Tsetup - Tskew)

If setup slack is positive, it means there is still some margin available in the timing path. On the other hand, a negative slack means that the paths violates setup timing check by the amount of setup slack. To get the path met, either data delay should be decreased or clock period should be increased.

Mitigating setup violation: Thus, we

can meet the setup requirement, if violating, by

1. Decreasing

clk->q delay of launching flop

2. Decreasing

the propagation delay of the combinational cloud

3. Reducing

the setup time requirement of capturing flop

4. Increasing

the skew between capture and launch clocks

5. Increasing

the clock period

Tackling hold time violation: Similarly, the equation for hold timing check is as below:

Tck->q + Tprop > Thold + Tskew

The parameter that represents if there is a hold timing violation is hold slack. The hold slack is defined as the amount by which L.H.S is greater than R.H.S. In other words, it is the margin by which timing path meets the hold timing check. The equation for hold slack is given as:

Hold slack = Tck->q + Tprop - Thold - Tskew

If hold slack is positive, it means there is still some margin available before it will start violating for hold. A negative hold slack means the path is violating hold timing check by the amount represented by hold slack. To get the path met, either data path delay should be increased, or clock skew/hold requirement of capturing flop should be decreased.

Mitigating hold violation: We can

meet the hold requirement by:

- Increasing

the clk->q delay of launching flop

- Decreasing

the hold requirement of capturing flop

- Decreasing

clock skew between capturing clock and launching flip-flops

Also read: